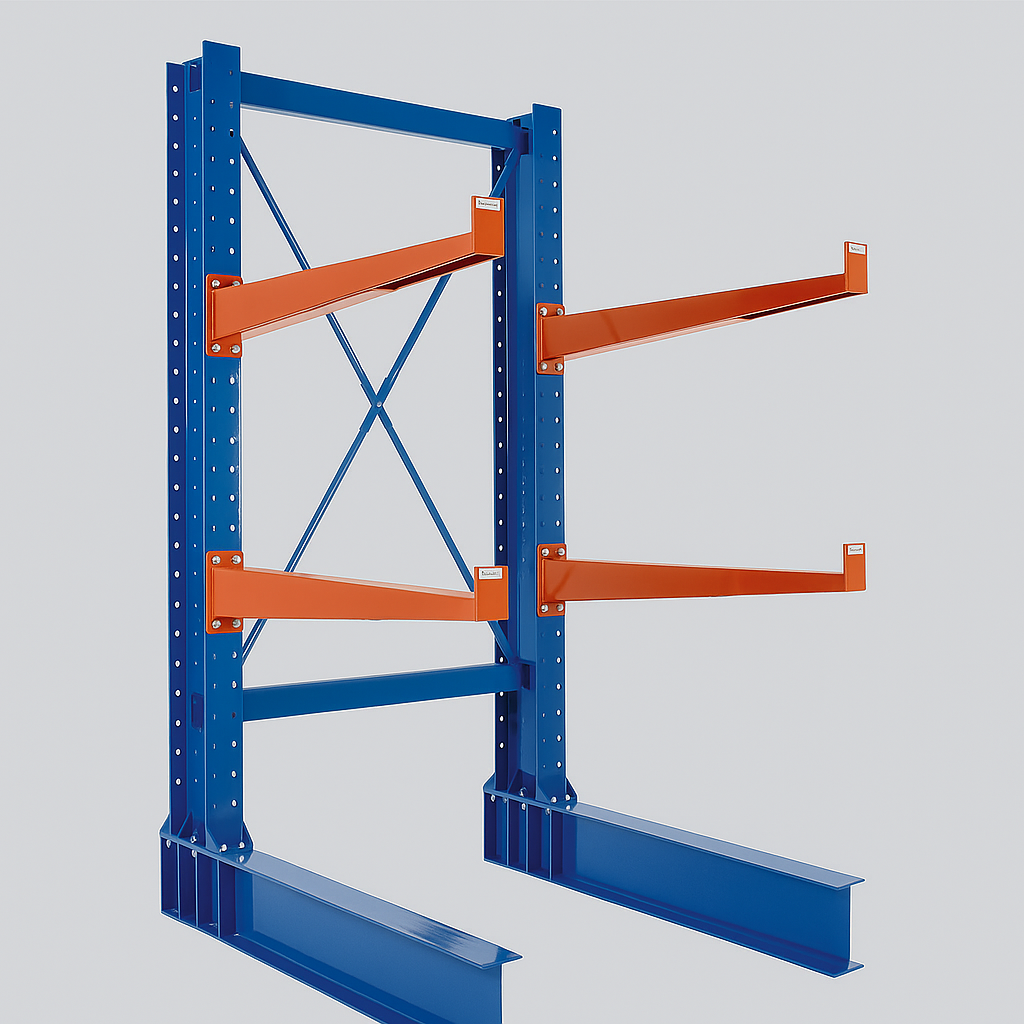

Cantilever Racks for Efficient Warehouse Storage

Optimize your warehouse with durable and versatile cantilever racks. Designed for easy access, high capacity, and customizable configurations—discover the perfect storage solution for long and bulky items.

Get a Free Quote

What Is a Cantilever Rack?

A cantilever rack is an industrial storage system designed for long, bulky, or irregularly shaped items. It features vertical columns, bases, arms, and braces, with an open-front design that uses outward-extending arms to support materials without vertical obstructions.

Commonly stored items include:

- Lumber, plywood, and drywall sheets

- Steel beams, pipes, and tubing

- Furniture and bulky household goods

- Carpet rolls and textiles

Types of Cantilever Racks

Light-Duty Cantilever Racks

Ideal for retail environments and smaller warehouses, light-duty cantilever racks are designed for lighter loads such as small lumber or lightweight materials. These racks offer flexibility and easy installation for businesses with limited storage needs.

Medium-Duty Cantilever Racks

A versatile option for general warehouses, medium-duty racks are suitable for storing lumber, plastics, or light steel. They balance strength and flexibility, making them ideal for moderate workloads in diverse settings.

Heavy-Duty Cantilever Racks

Engineered for industrial applications, heavy-duty cantilever racks are built to handle large lumber bundles, steel beams, and heavy construction materials. These racks provide maximum strength and durability for demanding environments.

Structural vs. Roll-Formed

Structural racks are made from hot-rolled steel for superior durability in heavy-duty applications, while roll-formed racks are lighter and easier to adjust, ideal for dynamic storage needs. Choose based on load weight and adjustability requirements.

Features & Benefits of Cantilever Racks

Open-Front Design

Allows easy loading and unloading without vertical obstructions, reducing handling time and improving accessibility for forklifts and side loaders.

Customizable Configurations

Available in single-sided or double-sided layouts to suit your warehouse space, with adjustable arms to accommodate various load sizes and shapes.

Heavy-Duty Capacity

Engineered to support thousands of pounds per level, ensuring safe storage for heavy materials like steel beams and large lumber bundles.

Adjustable Arms

Easily reposition arms along uprights to accommodate different load sizes, offering flexibility for changing inventory needs.

Durable Construction

Made from high-strength steel with powder-coated finishes, cantilever racks resist corrosion and wear, ensuring a lifespan of 10–15 years with proper maintenance.

Space Optimization

Maximizes vertical storage space and clears floor areas, improving warehouse organization and operational efficiency.

Forklift-Friendly

Designed for seamless integration with forklifts and side loaders, reducing handling time and enhancing workflow efficiency.

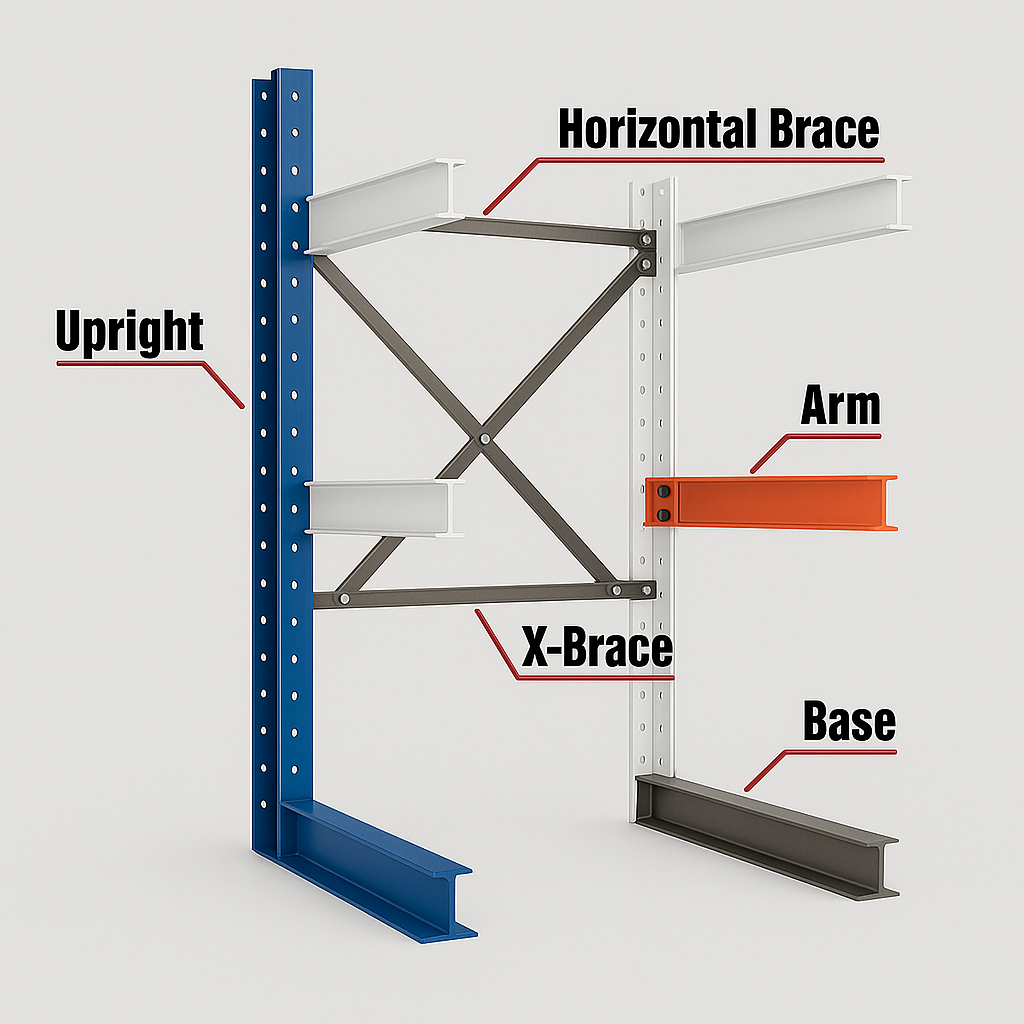

Cantilever Rack Components

Bases

Provide stability and anchor the rack to the floor, counterbalancing heavy loads to prevent tipping.

Uprights (Towers)

Vertical columns that support arms and braces, forming the backbone of the cantilever system.

Arms

Extend outward to hold materials; available in straight or inclined designs for various load types.

Braces

Connect uprights to add structural strength and stability to the rack system.

Decking (Optional)

Wire mesh, steel panels, or lumber decking can be added to convert arms into full shelf levels for mixed storage.

Cantilever Rack Accessories

Arm Lips/End Stops

Prevent materials from rolling off the arms, ensuring safe storage of cylindrical or loose items.

Pipe Stoppers

Designed to securely store pipes and tubing, preventing movement and ensuring safety.

Decking Options

Plywood, wire mesh, or steel decking for mixed storage of smaller or irregularly shaped items.

Mobile Bases

Allow racks to be mounted on rolling carriages for high-density, movable storage solutions.

Protective Guards

Floor-mounted guards protect bases and uprights from forklift impacts, extending rack lifespan.

Designing Your Cantilever Racking System

When designing your cantilever racking system, consider the following:

- Inventory Profile: Assess the length, weight, and shape of stored materials to select appropriate arm and upright sizes.

- Warehouse Layout: Account for ceiling height, aisle width, and forklift access to optimize space and accessibility.

- Future Scalability: Choose modular systems that allow for easy expansion as your storage needs grow.

- Traffic Flow: Position racks to minimize handling time and maximize operational efficiency.

- Safety Standards: Ensure compliance with OSHA and local building codes to maintain a safe working environment.

Determining Cantilever Rack Weight Capacities

The load capacity of a cantilever rack depends on several factors:

- Arm Capacity: Each arm is rated individually; total load must be evenly distributed across arms.

- Upright Capacity: Determined by the total weight supported by the column, including all arms.

- Base Strength: Bases must counterbalance loads to prevent tipping or structural failure.

- Load Distribution: Always balance weight evenly across arms and levels to maintain stability.

How to Choose the Right Cantilever Rack

Load Capacity

Match rack strength to your heaviest material to ensure safe and reliable storage.

Material Type

Consider the type of material (lumber, steel, furniture) to select appropriate arms and accessories.

Available Space

Measure ceiling height and forklift clearance to ensure proper fit and accessibility.

Single vs. Double-Sided

Choose single-sided racks for wall placement or double-sided for free-standing storage.

Growth Potential

Opt for modular racks to allow for easy expansion as your storage needs grow.

Safety Considerations

Follow Weight Ratings

Adhere to manufacturer-specified weight capacities to prevent rack failure.

Secure Anchoring

Ensure bases are securely anchored to the floor to maintain stability.

Forklift Training

Provide training for operators handling long loads to ensure safe operations.

Regular Inspections

Inspect racks regularly for wear, cracks, or damage to maintain structural integrity.

Protective Guards

Install guards to protect bases and uprights from forklift collisions.

Load Labeling

Use clear labeling to indicate weight capacities and load limits on racks to prevent overloading.

What Our Clients Say

“We were struggling to store our lumber safely and efficiently until we installed cantilever racks from Pallet Storage Solutions. The difference in organization and accessibility was immediate.”

Michael R., Construction Supply Manager“These racks are built tough. We use them for steel pipes and they handle the weight without issue. Highly recommend for anyone dealing with oversized materials.”

Jennifer T., Warehouse Supervisor“The team at Pallet Storage Solutions helped us design the perfect cantilever system for our space. Installation was smooth, and it’s made a huge difference in our productivity.”

James K., Operations DirectorFrequently Asked Questions (FAQs)

What is a cantilever rack used for?

How much weight can a cantilever rack hold?

Are cantilever racks adjustable?

What’s the difference between single-sided and double-sided cantilever racks?

Do I need professional installation?

Transform Your Warehouse Storage Today

Ready to optimize your warehouse with durable, space-saving cantilever racks? Contact Pallet Storage Solutions for a free consultation and quote tailored to your needs. Our experts will design the perfect rack system to boost efficiency, enhance safety, and maximize space.

Call: (734) 621-5052 Get a Free Quote